Welcome to MintBio Huitong New Materials (Yangzhou) Co., Ltd website!

The New Era Biomass Degradation Material Polylactic Acid, the "Key to the Future" of Green

Time:2023-04-18 09:19:10 Visits:513

Plastic has brought many conveniences to our lives, and we use many plastic products in our daily life. But for plastics, many people have a common impression that they are not environmentally friendly. This is because commonly used petroleum based plastics are difficult to degrade in natural environments, and their pollution control is also a global challenge.

In recent years, issues such as "white pollution", "microplastics", and "garbage continent" have received widespread attention. We are increasingly paying attention to the burden that non degradable plastics bring to nature, and human society's restrictions on non degradable plastics have become a mainstream trend. However, plastic products are ubiquitous in our daily lives. As a result, degradable plastics have gradually become a new trend.

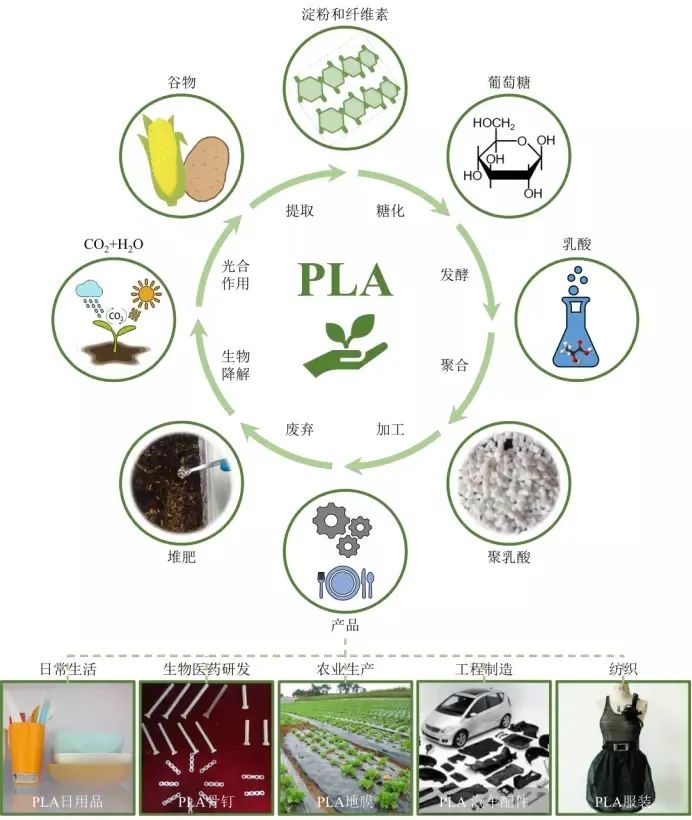

To this end, scientists have proposed a new concept of "originating from nature and returning to nature" and developed a synthesis route that converts biomass such as corn into biodegradable Poly (lactic acid) (PLA) plastics. Through chemical magic, feasible solutions have been provided for plastic pollution control. This plastic, which is converted from plant starch, has excellent biodegradability and is environmentally friendly due to its preparation process that eliminates environmentally friendly petrochemical raw materials.

The popularization of PLA can effectively reduce the use of non degradable plastics, which is of great significance for the treatment of plastic pollution. So, how is PLA gradually transformed from biomass such as corn, and how is it replacing traditional petroleum based plastics that have flourished for centuries in daily life, biopharmaceutical research and development, agricultural production, textiles, engineering manufacturing, and other aspects? Let's explore!

PLA cycle regeneration process and its application (Image source: self-made, some illustrations cited from references 26-29)

The "Magic" of Transforming Crops into Plastics

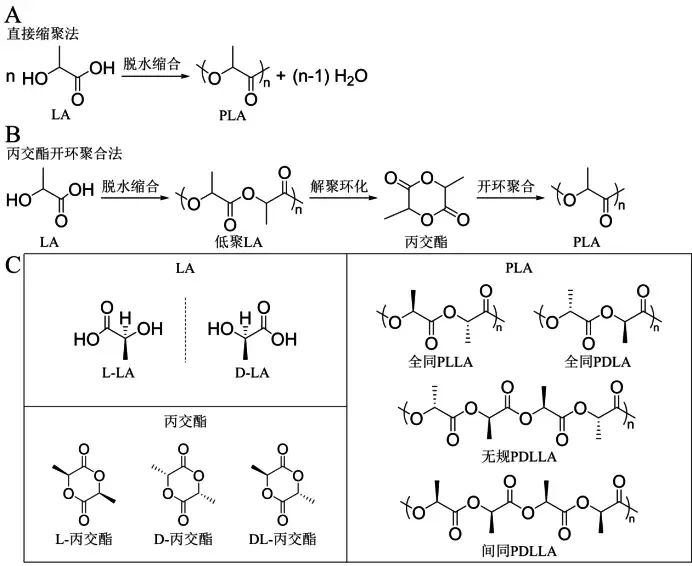

PLA is an aliphatic polyester made from lactic acid (LA) through oligomerization, cyclization, polymerization, and other processes. The conversion process of PLA is as follows - chemists can efficiently convert starch extracted from crops such as corn into LA through hydrolysis and microbial fermentation steps, and further convert it into PLA through condensation polymerization or ring opening polymerization, achieving the "magic" of turning crops into plastics.

Due to the presence of both hydroxyl groups (− OH) and carboxyl groups (− COOH) in the LA monomer, condensation reactions can occur with the carboxyl and hydroxyl groups of another LA monomer, respectively. In this way, LA monomers undergo alternating reactions to obtain high molecular weight PLA materials.

So, why didn't such environmentally friendly materials get widely used in the first place? In fact, this process is not so simple. There are many chemical and engineering problems and bottlenecks in the preparation process. For example, the water molecules (H2O) generated during the condensation reaction cannot be discharged in a timely manner, which will greatly inhibit the reaction process; In addition, the more stringent reaction conditions have also reduced the potential of this scheme for industrial production.

However, now the plan for preparing PLA has been improved, making the entire process more controllable. The existing mainstream route for industrial production of PLA, the ring opening polymerization of lactide, can achieve controllable synthesis of PLA molecules.

However, in order to obtain PLA plastics that meet daily needs, relying solely on specific molecular weights is not enough, and progress in processing technology and modification methods is also important. Next, we will introduce the characteristics of PLA and how to transform PLA into various common items in daily life.

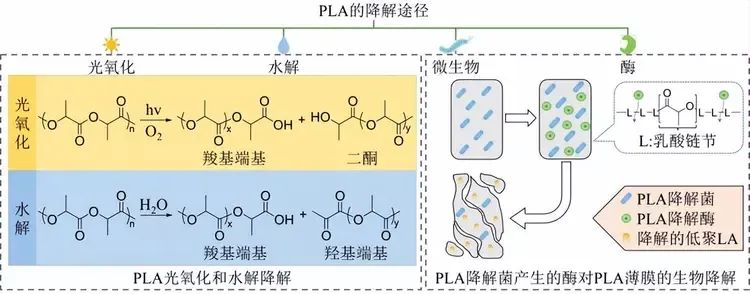

Schematic diagram of the main degradation pathways of PLA: PLA photooxidation and hydrolysis (left), biodegradation of PLA by enzymes produced by microorganisms (right) (Image source: self-made)

The Properties and Modifications of PLA

The Properties and Modifications of PLA

When it comes to the properties of PLA, it should be pointed out that LA contains a chiral carbon atom, which can be divided into L-lactic acid (L-LA) and D-lactic acid (D-LA). The former has the same structure as the LA metabolized by the human body, but high intake of D-LA can have toxic side effects.

Therefore, commercial PLA is generally L-LA synthesized levorotatory PLA (PLLA). In addition, there are also dextral PLA (PDLA) synthesized from D-LA, as well as poly (D, L-LA) (PDLLA) synthesized from L-LA and D-LA copolymerization.

From the chemical structure of PLA, it can be inferred that the large number of ester bonds in its main chain is the key to its good degradation performance. Under composting conditions (high temperature, high humidity, and microbial action), PLA can be fully degraded into H2O and carbon dioxide (CO2) in just a few months, achieving cyclic regeneration through plant photosynthesis.

In addition, PLA can also be degraded in the human body, and its hydrolysate LA can be absorbed and utilized by the human body. This excellent biocompatibility demonstrates its high application value in the field of biomedicine.

Schematic diagram of the main degradation pathways of PLA: PLA photooxidation and hydrolysis (left), biodegradation of PLA by enzymes produced by microorganisms (right) (Image source: self-made)

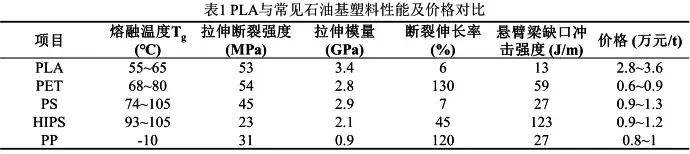

In addition to its excellent ecological friendliness, biodegradability, and biocompatibility, PLA also has physical properties comparable to traditional petroleum based plastics.

Note: PET refers to polyethylene terephthalate, PS polystyrene, HIPS refers to high impact styrene, and PP refers to styrene (data source: Reference 10)

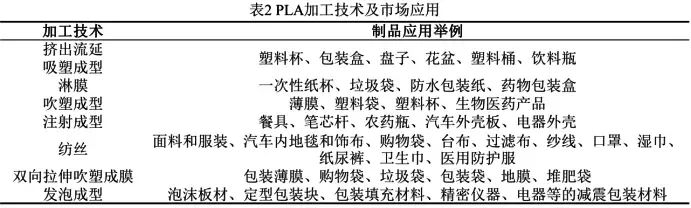

PLA, due to its excellent thermal formability, can be processed into various plastic products through extrusion molding, suction molding, film coating, blow molding, injection molding, fiber spinning, foaming, and other methods, which has a wide range of applicability.

(Data source: Development Plan for Biobased Materials Industry in Bengbu City)

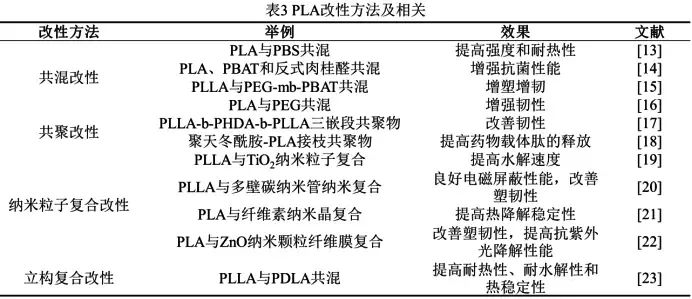

However, PLA also exposes some shortcomings in its application, such as susceptibility to brittle fracture, uncontrollable degradation cycle, and insufficient biocompatibility.

Scientists are also actively seeking solutions to these issues with PLA. For example, the toughness, controllability of degradation cycle, hydrophilicity, and antibacterial properties of PLA have been further improved through methods such as blending, copolymerization, nanocomposition, and stereocomposites, greatly expanding the application range of PLA.

Note: PBS is polybutylene succinate, PBAT is polybutylene adipate, and PHDA is poly (hexamethylene decamethylene adipate)

Application and Development of PLA

PLA is actually not unfamiliar, and you may encounter it in various aspects of your life.

From the perspective of food, with the rapid development of the delivery, express delivery, and catering industries in recent years and the joint promotion of policies such as the "plastic ban" issued by the country, the commercialization of PLA products has made great strides forward. In addition to paper straws, PLA straws are also commonly used when drinking milk tea in our daily lives.

From a clothing perspective, PLA clothing made by blending PLA with antibacterial agents is favored by consumers.

From the perspective of daily use, PLA, which has been plasticized and toughened, can be applied to daily necessities and children's toys to effectively prevent children from ingesting harmful plastic particles.

From a medical perspective, by improving the hydrophilicity and biocompatibility of PLA and strengthening the control of PLA degradation time, biomedical polymers such as PLA vascular stents, absorbable materials, and surgical sutures have gradually been put into use.

In addition, materials such as PLA plastic film and sand barrier have a broad market, which is of great significance for environmental governance and has a very large application market.

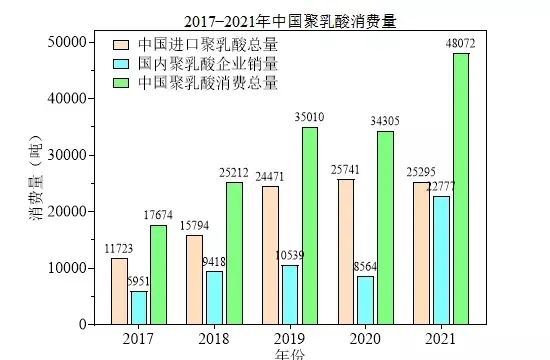

Statistical Chart of PLA Consumption in China from 2017 to 2021 (Data Source: Guanyan Report Network)

Nowadays, the domestic PLA production capacity is about 250000 tons/year, but in recent years, the demand for PLA has shown an upward trend. At present, the total production capacity of PLA production lines under construction or planned by various enterprises has exceeded 1.5 million tons per year. It is expected that PLA will be more widely popularized in the next 3-5 years.

Despite the rapid development of the domestic PLA industry, it still faces two major challenges. Firstly, the key technologies in the industry urgently need to be improved, and secondly, the production cost of PLA needs to be further reduced. At present, the production cost of PLA is three times or even more higher than that of commonly used petroleum based plastics, making it difficult to replace traditional plastics. In addition to reducing costs in production technology, it is also necessary to strengthen the layout of the PLA industry, accelerate the construction of PLA production lines, and reduce their costs to the "cabbage price" equivalent to traditional plastics

conclusion

Currently, PLA has gained a foothold in daily life, biopharmaceutical research and development, agricultural production, textiles, engineering manufacturing, and other fields due to its excellent biodegradability, biocompatibility, and wide applicability. However, compared with petroleum based plastics, PLA's higher production costs and complex production processes are still the main reasons hindering its widespread popularity.

Nowadays, driven by the implementation of the "dual carbon" strategy and the ban on plastic production, PLA has ushered in new opportunities for market development. This type of plastic produced from grains has achieved the environmental protection concept of "originating from nature and returning to nature", indicating the direction for solving the problem of plastic pollution. Perhaps one day, we can fully popularize environmentally friendly and biodegradable plastics, not only enjoying the convenience brought by plastic products, but also achieving harmonious coexistence with nature.

Bio-based Material

Fully Degradable Material

Biology Base Product

Fully Degraded Product

Mobile Site

Copyright © 2021 MintBio Huitong New Materials (Yangzhou) Co., Ltd Copyright All Rights Reserved! Record Number:Su ICP No. 2021024217 Technical Support: Jiangsu Ruizhijie Technology Co., Ltd